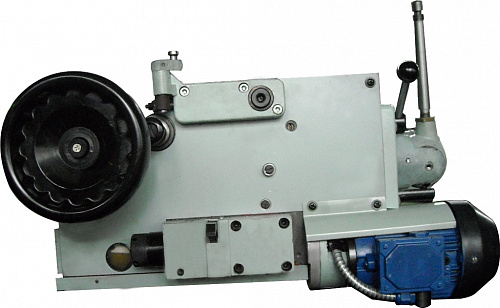

The apron is designed to convert the rotational movement of the lead screw and the drive shaft into the longitudinal movement of the carriage and the transverse movement of the caliper, as well as for manual control of these movements during the operation of the machine (turning on and off the working and accelerated movements of the carriage and caliper, reversing movements, etc.).

The apron can be equipped with a friction clutch control mechanism.

The built-in own electric motor allows to carry out:

- accelerated movement of the carriage and caliper;

- work on the stop with automatic shutdown of the feed upon contact with the stop at the moment of increasing the load on the rack and pinion.

Climatic version of the apron is UHL4 and 04 (for tropical climate) according to GOST 15150.

It is allowed to use an apron for machines with the following data:

- the greatest traction force transmitted by the apron mechanism, kN (kGs) - 10 (1000).

RU

RU EN

EN BY

BY